|

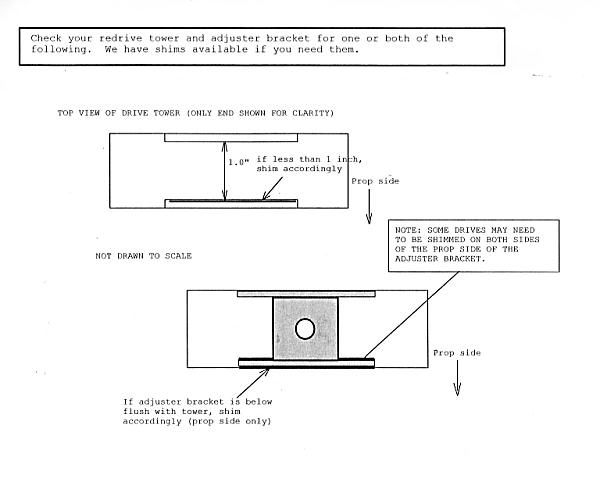

The information contained in this document is intended for the sole use of Canadian Challenger owners and is strictly proprietary and confidential. The Challenger design has evolved continuously over the past two decades so the teething problems inherent in brand new designs were sorted out long ago. In the early years the Challenger's Evolution focused on durability and robustness thus allowing the recent focus on performance and comfort. There has been only one Challenger service bulletin issued in the last decade! This bulletin, issued in 2004, refers to some of the more recent 2.6-to-1 redrives. Only some redrives are affected but we urge all owners to review this notice. 2.6-to-1 Reduction Drive Shim Notice - Published September 2004 Quad City has advised that on some 2.6-to-1 redrive towers the grooves for the stainless steel height adjuster bracket are slightly deeper than usual. On these towers 1 mm shims are required for the stainless steel height adjuster bracket. Since this issue was brought to light grooves are checked at the factory and if shims are required they are welded to the bracket before shipping. However prior to this time some redrives needing shims were shipped without them. The most obvious way to tell if your redrive tower has this characteristic is if your cog belt tracks on the aft edge of the upper pulley or rubs on the rear flange of the lower pulley (creating some black dust or glassing on the belt). A more subtle way is to check that on the prop side the adjuster bracket should stand out slightly from the surface of the tower so the upper pulley's thrust spacer rests on the stainless steel of the adjuster bracket, not on the tower. Another signal could be having to repeatedly tighten the large castle nut. All of the above symptoms should be detected by attentive owners during routine preflight inspections. Hopefully you the reader are indeed attentive! Left uncorrected for long enough this situation could cause problems

such as: This notice will inform you how to tell if your reduction drive needs

shimming. If your redrive requires shimming be sure to check for the wear items

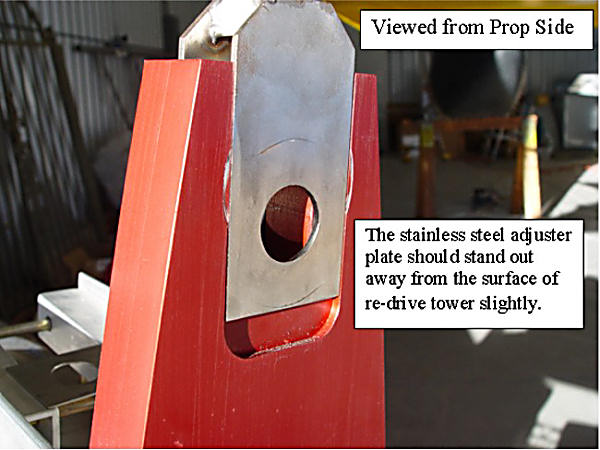

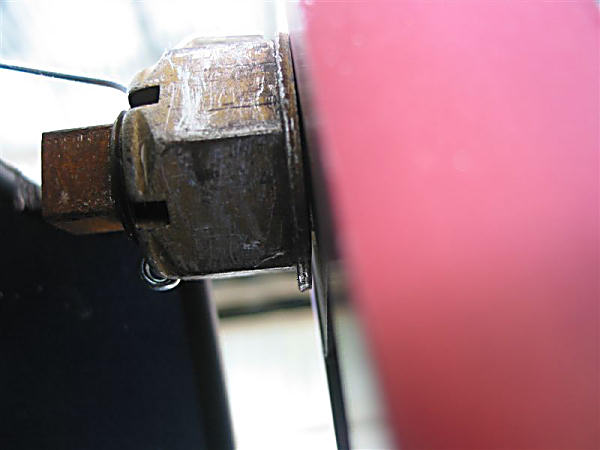

above! When everything is copasetic, the redrive tower is exactly one inch thick at the grooves and the height adjuster plates are exactly one inch apart. On the prop side of the tower the height adjuster bracket should stand out slightly from the tower so the thrust spacer rests on the bracket, not on the surface of the tower:

If your bracket protrudes slightly from the tower and is aligned with the tower and the thrust spacer does not contact the tower then you don't need to shim. If your tower is less than one inch thick at the grooves then the lower portion of the bracket will eventually sink to slightly below the surface of the tower and allow the thrust spacer to rest on the surface of the tower rather than on the bracket. This will erode semi-circular indents in the aft surface of the tower and the bottom of the height adjuster bracket will dig into the tower's aft groove:

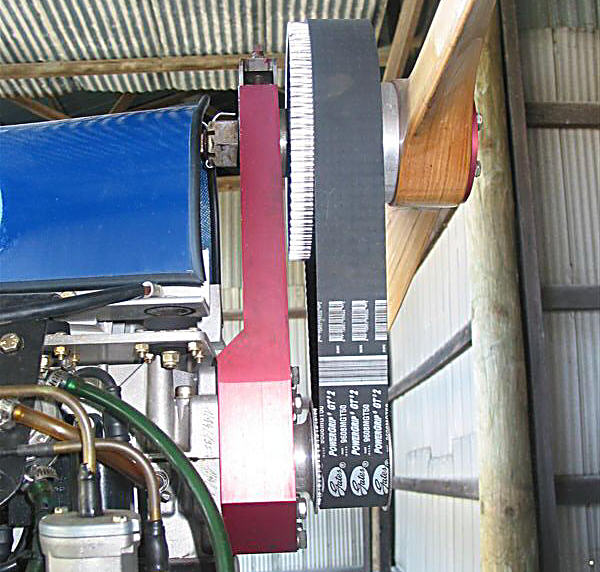

Without shimming, over time the upper pulley will sag slightly downward to aft causing the cog belt to track on the rear portion of the upper and lower pulleys:

If your belt tracks nicely near the centres then you probably don't

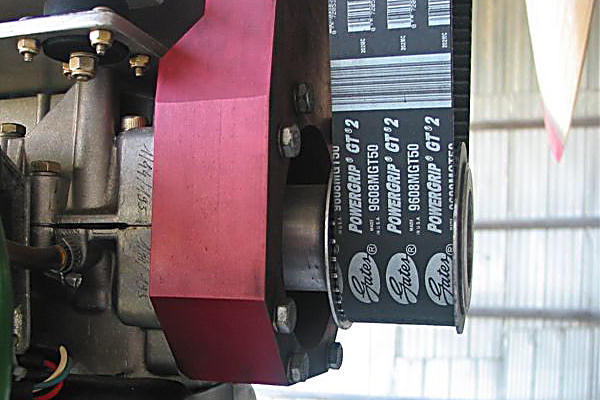

need to shim. If your cog belt tracks aft of centre it will press out on the lower pulley flange and cause glassing on the rear edge of the belt plus black dust on the tower:

This pressure could possible loosen the flange! Note that whether

or not your redrive needs shimming, as part of your preflight inspections

you should always check the flange on the lower pulley to ensure it is

seated properly! (Another possible cause for the belt tracking aft of centre is if it was set too tight thus preventing the prop shaft from coming up to horizontal when the large castle nut is tightened. In this case loosen the belt slightly - no shims.) The large castle nut normally doesn't require adjustment after being torqued to 125 ft-lbs. Repeatedly having to tighten this nut is a sign shimming is needed:

For redrives which require shimming Quad City has provided free 1mm shims to elevate the stainless steel height adjuster bracket in the tower groove:

If you have questions or need shims contact us or Quad City at 309-764-3515. The key to success if your drive needs shimming is early detection!

To learn and see more order our comprehensive information package and video! |